Capabilities

Whether your project demands primary vacuum induction melting, secondary remelting or even triple-melt capabilities, WASA has reliable facilities and outstanding commitment to quality to deliver on your needs.Superalloy Ingot, Billet, and Bar

WASA produces superalloy ingot, billet and Bar for forging and ring rolling applications for a range of aerospace, power generation and oil & gas applications.

In addition to IN718 WASA produces over 40 wrought alloy grades some of which include Waspaloy, IN625, X750, 13/8, U500, IN725, IN925, R41, IN945, IN945X, S188, C263, IN907,IN909.

VIM Superalloy Master Bar Stock

WASA also produces VIM superalloy ingots either for use in casting applications or input stock for powder material for aerospace and power generation applications. The remelt ingot is produced in a variety of diameters between 3 inch (75mm) and 7 inch (175mm).

WASA supplies master barstock used in equiaxed, columnar grain, single crystal and powder atomisation applications. With a total portfolio of over 60 seperate grades examples of the major alloys produced are IN738, GTD111, Rene 108, MM247, IN792, FSX 414, L605, MM002, C1023, IN713, IN 718, R77, PWA1455LS, PWA1475LS, IN100, R88, RR1000, ME16, SR99, WSX1 and WSX 2.

Vacuum Induction Furnace

WASA’s vacuum induction furnace has a melting capacity of 5 tonnes (11,000 lbs), 10 tonnes (22,000 lbs) or 15 tonnes (33,000 lbs) and can produce input stock for master melts or secondary and tertiary melting.

Arc Remelting

WASA’s VAR furnaces have upgraded control systems for precision melting control. Ingots can be supplied via the double melt VIM + VAR process or the triple melt VIM + ESR + VAR process for premium quality rotating grade applications.

Ingot Sizes:

Electro Slag Remelting

WASA operates modern Consarc and ALD manufactured ESR furnaces for the supply of round double melted VIM + ESR ingots or as feedstock for the VAR in the triple melt VIM + ESR + VAR process.

1 x Consarc ESR

Nominal 18” (457mm) diameter

9260lbs (4200Kg) finished ingot weight

1 x ALD ESR

Nominal 18” (457mm) diameter

9260lbs (4200Kg) finished ingot weight

Large diameter capability up to 34” on request

Forging Capabilities

Davey 2300MT Open Die Press:

Auxillary Equipment:

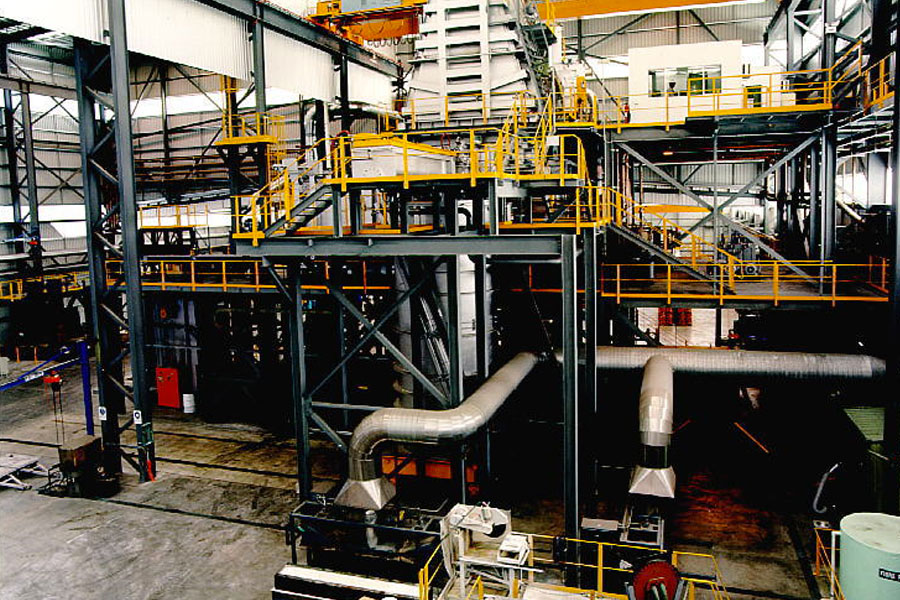

WASA ALBURY FACILITY

OVERALL FORGE

WASA’s Albury facility supplies shaped nickel alloy forgings for oil and gas and power generation applications together with a range of steel forgings for shafts, racks, rings etc for mining and general engineering within Australia.

The Highest Standard of Process Control

At WASA, a highly regarded team of professionals which includes chemists, metallurgists, engineers and technicians, applies the highest standard of process control using the very latest in analytical equipment and ensures that the most exacting requirements are achieved.